Connecting a CNC machine requires careful setup and configuration, guided by the machine’s manual. This ensures optimal performance, safety, and reliable communication between the CNC machine and control systems.

Overview of CNC Machine Setup and Configuration

Setting up and configuring a CNC machine involves a multi-step process to ensure proper communication and functionality. Begin by reviewing the CNC machine manual, which provides specific instructions tailored to your device. Hardware setup includes connecting power supply lines, Controller panels, and ensuring all wiring matches the provided diagrams. Software configuration involves installing and setting up control programs, such as ConnectCNC, to manage CNC operations. Proper port configurations and firmware updates are essential for seamless communication. Additionally, integrating external equipment, like spindles or VFD systems, requires careful adaptation. Always refer to the manual for detailed wiring schematics and step-by-step guidance. Proper setup ensures efficient performance, reduces errors, and optimizes production capabilities. Consulting the manual during each step helps avoid common issues and guarantees a reliable connection.

Importance of Consulting the CNC Machine Manual

Consulting the CNC machine manual is crucial for a smooth and error-free setup process. The manual provides detailed instructions tailored to your specific machine, ensuring proper configuration and safe operation. It outlines hardware requirements, wiring diagrams, and software settings, reducing the risk of connection issues. Troubleshooting sections help resolve common errors, while firmware update guides keep your system optimized. Referencing the manual prevents misconfigurations, which can lead to operational failures or safety hazards. Additionally, it serves as a reference for optimizing performance and integrating external equipment. Always prioritize the manual for precise instructions, ensuring your CNC machine runs efficiently and effectively. This resource is invaluable for both beginners and experienced operators, guaranteeing a reliable connection and maximizing productivity.

Configuring the CNC Machine

Configuration involves setting up software and hardware according to the CNC machine manual. This includes installing drivers, configuring ports, and ensuring all components are correctly connected for seamless operation.

Software Configuration for CNC Communication

Software configuration is critical for establishing reliable CNC communication. Begin by installing the appropriate drivers and CNC control software, such as ConnectCNC, ensuring compatibility with your machine. Refer to the CNC machine manual for specific instructions. Configure the software settings, including baud rate and data bits, to match your machine’s specifications. Use the manual to locate parameter values or start with default settings. Once configured, test the connection by sending a test file to the machine. Proper software setup ensures efficient data transfer and precise machine operation. Always update firmware if prompted during the initial connection to maintain optimal performance and functionality.

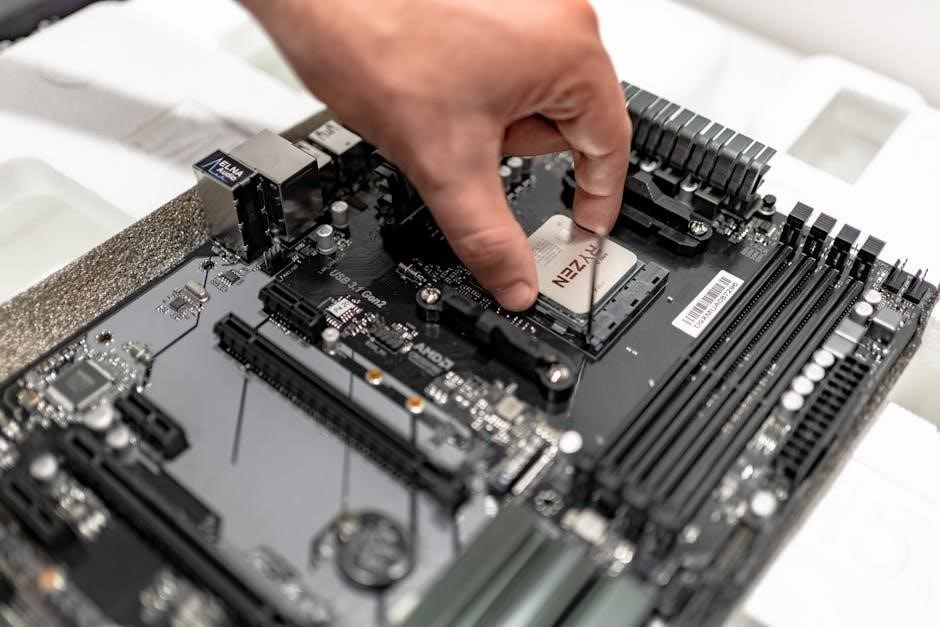

Hardware Setup and Wiring Diagrams

Proper hardware setup and wiring are essential for connecting your CNC machine. Start by identifying the connection type—USB, Ethernet, or Serial—and ensure all cables are securely connected. Refer to the wiring diagrams provided in the CNC machine manual to connect the controller panel, power supply, and external equipment. Follow the manufacturer’s guidelines to avoid electrical issues. Use the 14-pin control cable for integrating external devices, and ensure all connections are tightly secured. Double-check the wiring against the manual to prevent errors. Correct hardware setup ensures reliable communication and safe operation of the CNC machine, minimizing the risk of malfunctions or damage.

Connecting the CNC Machine to a Computer

Connecting your CNC machine to a computer involves selecting the right connection type (USB, Ethernet, or Serial) and configuring settings as per the manual. Ensure proper communication and compatibility for seamless operation.

Choosing the Right Connection Type (USB, Ethernet, Serial)

Selecting the appropriate connection type for your CNC machine is crucial for reliable communication. USB connections offer simplicity and high-speed data transfer, ideal for modern CNC machines. Ethernet provides a stable and long-distance connection, suitable for industrial settings. Serial (RS-232) connections are legacy options, commonly used for older CNC systems. Each connection type has specific requirements, so refer to your CNC machine’s manual to determine compatibility. Proper selection ensures efficient data transfer and minimizes setup issues. Always verify the port availability on both the CNC machine and the computer to establish a seamless connection. This step is essential for successful CNC operation and optimal performance.

Setting Up Port Configurations in ConnectCNC

Configuring ports in ConnectCNC is essential for establishing communication between your CNC machine and computer. Begin by launching ConnectCNC and navigating to the port settings section. Refer to your CNC machine’s manual to identify the correct COM port and baud rate. Enter these values in the software to ensure compatibility. If using a USB-to-serial adapter, install the appropriate drivers beforehand. Test the connection by sending a command to the CNC machine. A successful response confirms proper setup. Regularly update ConnectCNC to access new features and improvements. Proper port configuration ensures reliable data transfer, enabling efficient operation and minimizing errors during production.

Troubleshooting CNC Connection Issues

Common issues include incorrect port settings, outdated firmware, or faulty wiring. Consult the manual for error codes and solutions. Ensure all connections are secure and configured properly.

Common Errors During CNC Machine Setup

One of the most frequent issues during CNC machine setup is incorrect port configuration. Users often overlook the specific settings required for their machine’s communication ports, leading to failed connections. Another common error is outdated firmware, which can cause compatibility problems with control software. Additionally, improper wiring connections, such as loose or misplaced cables, can disrupt communication between the CNC machine and the control system. It’s crucial to refer to the CNC machine manual for precise instructions on configuring ports and updating firmware. Ensuring all physical connections are secure and correctly routed can prevent many of these issues. Regular checks and maintenance are essential for smooth operation.

Firmware Updates and Maintenance

Firmware updates are essential for ensuring optimal CNC machine performance and compatibility with control systems. Upon initial connection, many CNC machines prompt for firmware updates, such as the Ready2Control system, which requires updating both the Pendant and Control Box. Regular firmware maintenance ensures that communication protocols remain stable and that new features are integrated. Users should always consult the CNC machine manual for specific update procedures, as methods can vary between models. Neglecting firmware updates can lead to connectivity issues or reduced functionality. Additionally, performing routine system checks and updates helps prevent errors and ensures smooth operation. Always verify compatibility before installing new firmware to avoid potential conflicts with existing hardware or software configurations.

Optimizing CNC Machine Performance

Optimizing CNC machine performance involves reducing setup time, minimizing blank waste, and enhancing operational efficiency. Regular maintenance and updates ensure peak productivity and consistency in manufacturing processes.

Reducing Setup Time and Improving Efficiency

Reducing setup time is crucial for improving CNC machine efficiency. By streamlining tool changes, fixtures, and program adjustments, manufacturers can minimize downtime. Implementing quick-change tooling systems and pre-configured jigs ensures faster transitions between jobs. Additionally, optimizing CNC programs to reduce cycle times and automating repetitive tasks can significantly boost productivity. Regular maintenance and firmware updates also play a key role in maintaining operational efficiency. By addressing setup inefficiencies and leveraging advanced CNC features, businesses can achieve higher output and lower operational costs, ensuring competitive manufacturing capabilities. Proper planning and organization of production runs further enhance efficiency, making the CNC setup process more effective and less time-consuming.

Best Practices for CNC Machine Operation

Adhering to best practices ensures safe and efficient CNC machine operation. Always consult the user manual for specific setup instructions and safety guidelines. Regularly update firmware to maintain optimal performance and security. Use high-quality cables and connectors to prevent communication errors. Implement a structured maintenance schedule to avoid unexpected downtime. Train operators thoroughly on CNC controls and software to minimize errors. Keep the work area clean and organized to prevent accidents. Utilize diagnostic tools to monitor machine health and address issues promptly. By following these practices, operators can maximize productivity, reduce risks, and extend the lifespan of their CNC equipment. Consistent adherence to these standards fosters a reliable and efficient manufacturing environment.

Advanced CNC Configuration

Advanced CNC configuration involves integrating wireless adapters and external equipment, enhancing machine functionality and connectivity for streamlined operations and improved manufacturing processes.

Using Wireless Adapters for CNC Connection

Wireless adapters provide a convenient and flexible way to connect CNC machines to networks, eliminating the need for physical cables. By installing a compatible wireless adapter, manufacturers can achieve seamless communication between the CNC machine and control systems. This setup enhances mobility and reduces the risk of cable damage, making it ideal for modern workshops. Ensure the adapter supports the CNC machine’s communication protocols, such as Ethernet or serial-to-wireless conversion. Configuration typically involves setting up IP addresses and ensuring network compatibility. Always refer to the CNC machine’s manual for specific guidance on wireless integration to maintain optimal performance and security.

Integrating External Equipment with CNC Controllers

Integrating external equipment with CNC controllers enhances functionality and streamlines production processes. This can include devices like spindles, VFDs, or sensors. Proper setup requires following the CNC machine’s manual and wiring diagrams. Ensure all connections align with the controller’s I/O configuration. Use the 14-pin control cable for compatible equipment, adapting as needed for custom setups. Configure settings in the CNC software to recognize external devices, enabling precise control. Regularly update firmware and consult technical manuals for troubleshooting. This integration optimizes performance, reduces errors, and supports advanced manufacturing capabilities. Always verify compatibility and follow safety protocols during setup to ensure reliable operation and minimize downtime.